Solutions for aesthetic control

Ease of implementation thanks to a standardized approach and classification using Artificial Intelligence

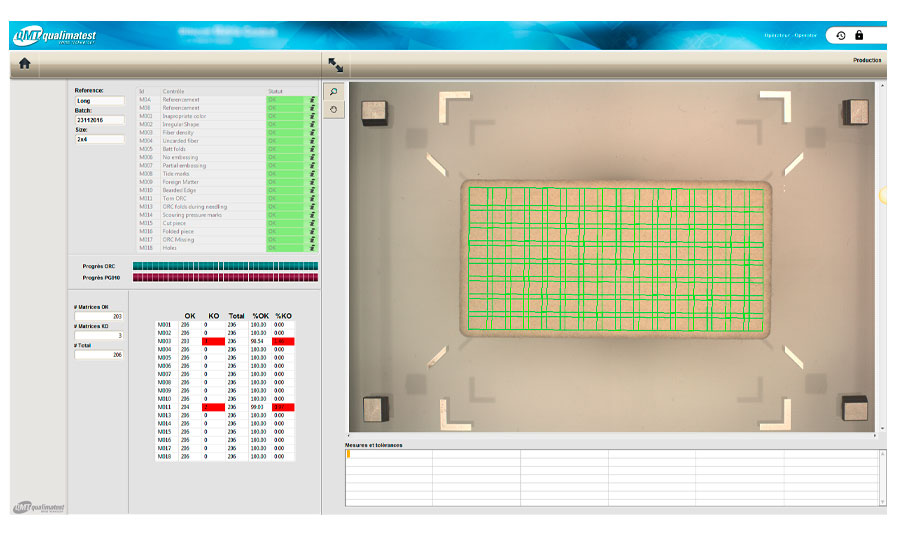

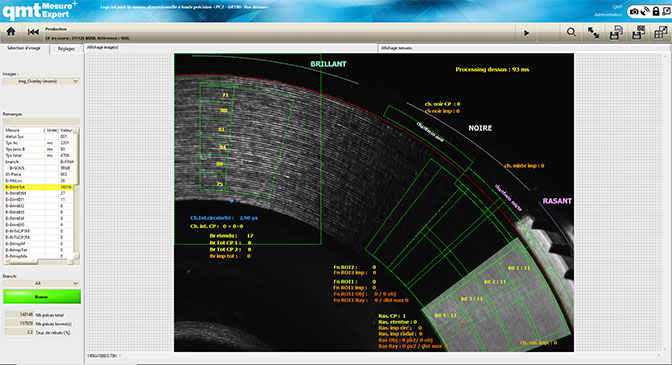

Automation of aesthetic control

Appearance is an essential characteristic of a product for reasons of appearance or for its function.

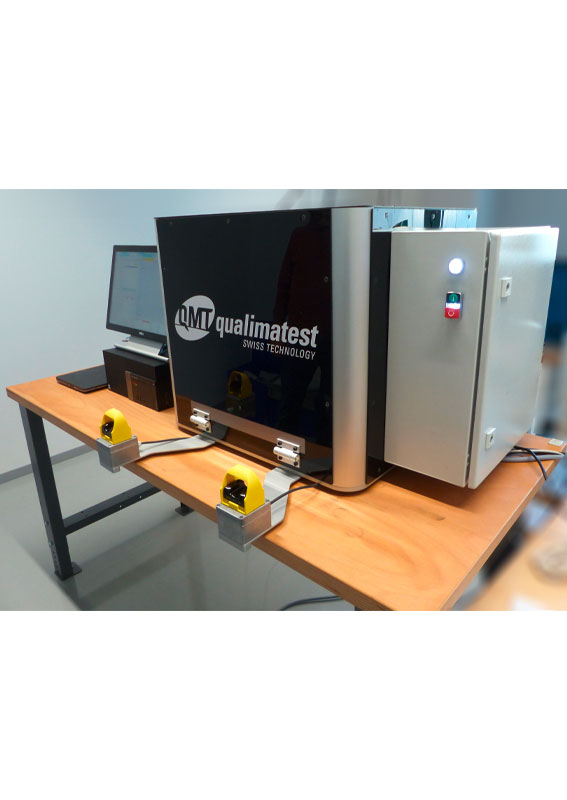

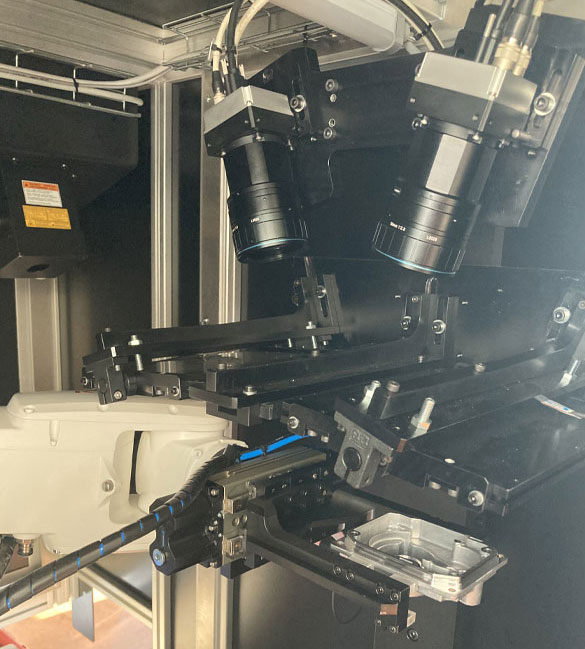

QMT offers turnkey solutions for aesthetic inspection of manufactured products. These solutions integrate high-performance optics, mechanical integration, and advanced software.

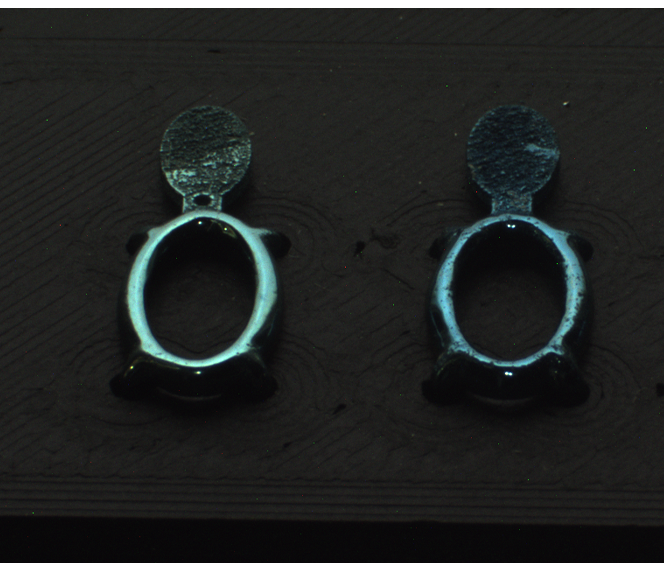

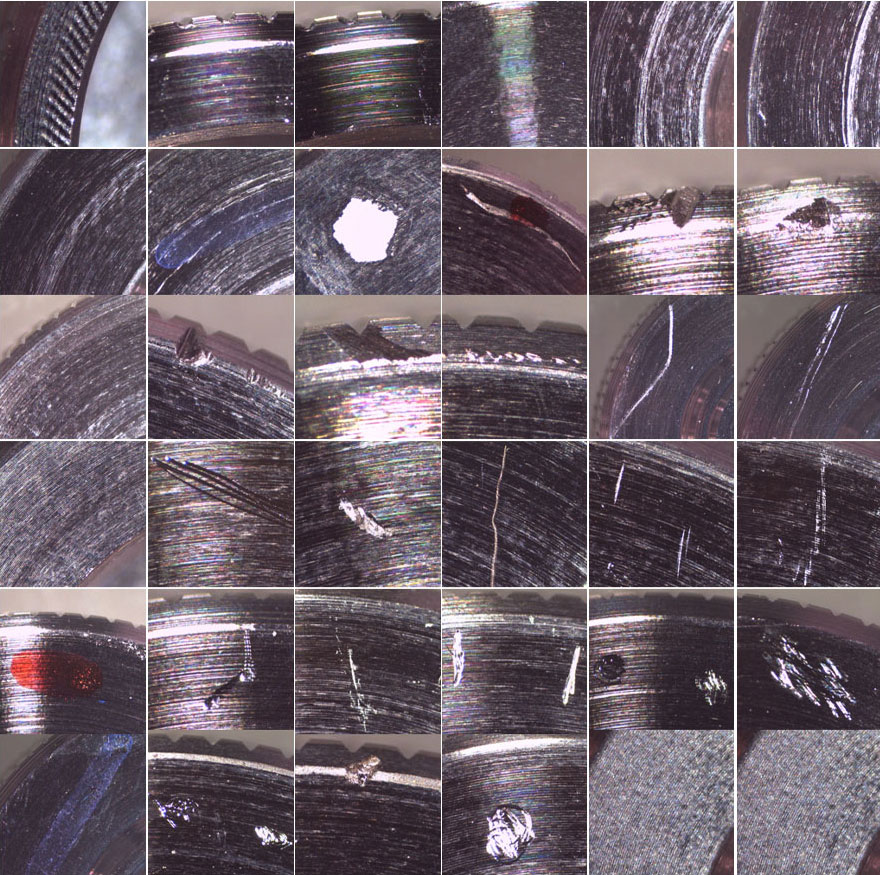

All aesthetic criteria can be automatically controlled: detection of defects (scratches, impacts, burrs…), surface characterization (texture, uniformity…) and measurement of perceived color.

QMT solutions are simple to implement, scalable, and customizable. Implementation is based on support using a standardized methodology and machine learning via artificial intelligence.

We contribute to our clients' development for lasting prosperity

Through vision, through hearing, through automated solutions integrating artificial intelligence, qmt limits the number of imperfections in what will or can be manufactured.

About qmtA team deployed across our two sites in Geneva and Chambéry

With our extensive know-how, we build a reliable partnership with our clients to develop solutions and support their success by improving quality and efficiency.

The qmt teamWe will never achieve perfection, but we work towards it every day.

qmt developed the Multimicro in 1991 (motorized image analyzer with automatic microhardness measurement), which was awarded a Credit Suisse prize. In 2015, qmt won the Geneva Canton Innovation Prize.

Historical

Colorimetric conformity

Aspect control

- Scratches caused by friction or machining, whether visible or microscopic

- Shocks or impacts related to handling or transport, which can alter the geometry of a part

- Burrs resulting from imperfect molding, drilling, or cutting

- Stains, dust or deposits that may originate from the manufacturing process or handling.

Surface conformity

- Texture: visual roughness, grain, micro-structure, pattern regularity

- Uniformity: homogeneity of the surface, absence of matte or glossy areas

- Gloss and reflection: control of the mirror-like appearance, haze, or level of light diffusion

- Flatness and waviness: checking the regularity and stability of the surface to detect any deformation that could alter the visual appearance or disrupt the assembly.

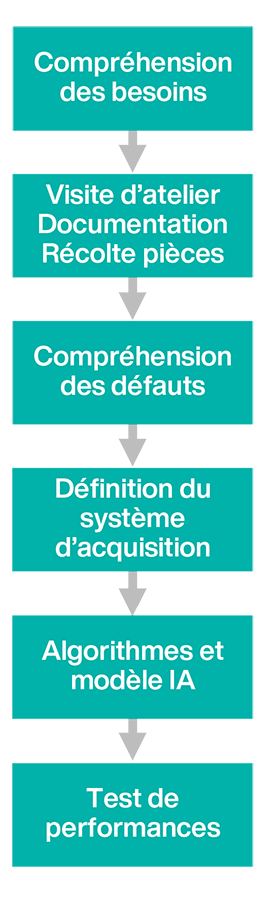

A standard approach

- Project and process management including formalization

- Understanding the reference control

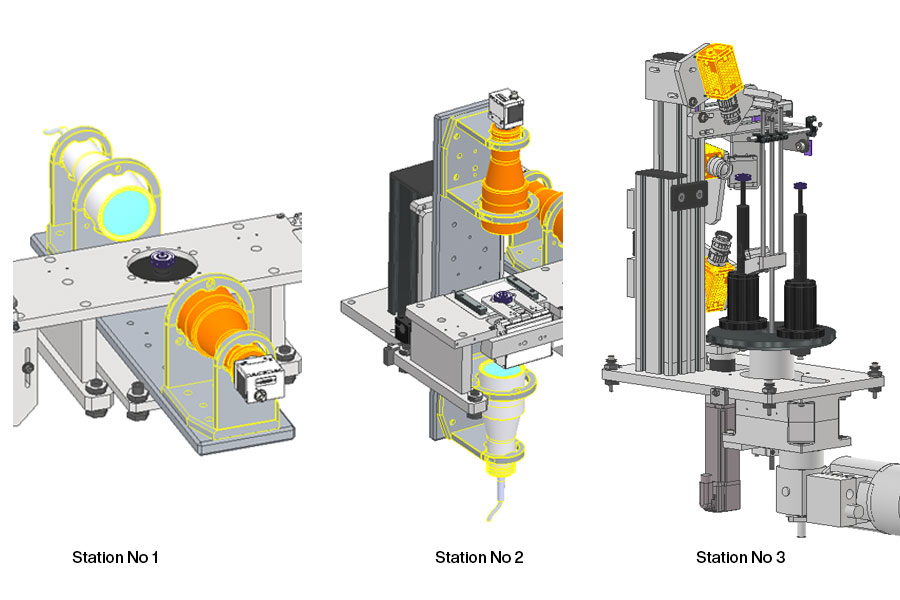

- Development of the acquisition solution

- Algorithm development

- Creation of the AI model

- Performance test

- Availability to allow QMT to understand the control

- Collection and qualification of the parts

- Qualification check after automatic evaluation (verification)

Customizable solutions to perfectly meet your needs

Standard products for dimensional control

Learning with artificial intelligence

Customized solutions developed based on customer specifications

Aesthetic inspections using linear cameras for the company Sonceboz

Dressing check