Advice and studies

Our approach is to offer a 360° service to our clients

Consulting – a 360° approach

We don't just design customized testing and quality control solutions; we go further by supporting our clients in optimizing their industrial processes. Thanks to our technical expertise and hands-on approach, we advise our clients on the best strategies to adopt, whether it's integrating new technologies, improving the performance of their existing systems, or ensuring the long-term viability of their equipment.

- With a team of Master and Black Belts, qmt can support you with various industrial performance issues.

- With over 35 years of expertise in testing and quality control, our technical experts support you in your control projects.

- Maintenance advice

- Tailored advice on testing strategy and quality control

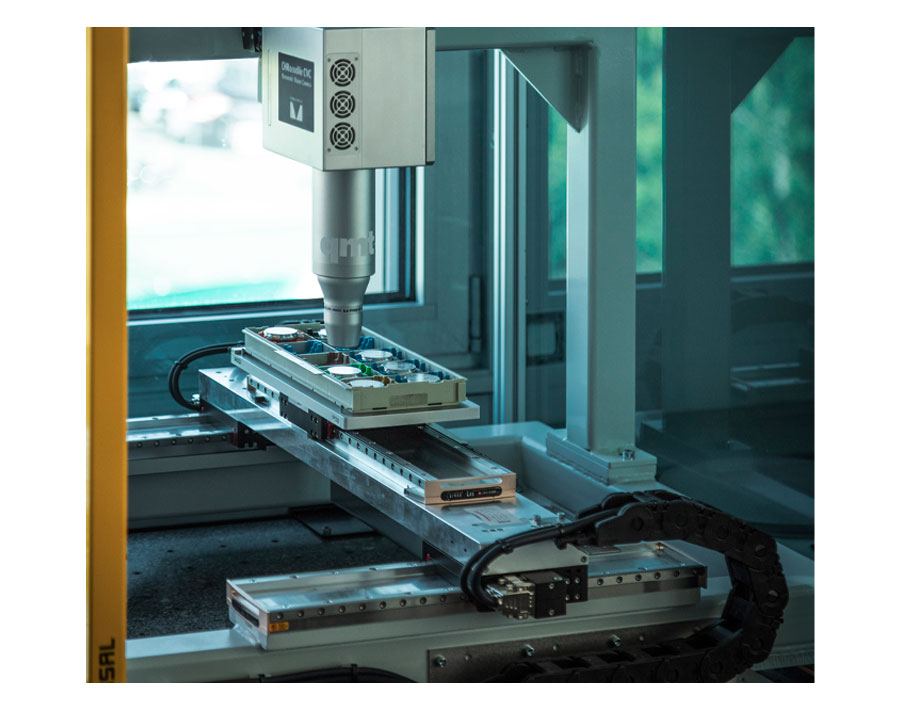

Creation of a Proof of Concept (POC) for aesthetic control

The infrastructure for QMT research and customer studies

To meet its clients' needs in automated quality control and testing, QMT 's experts sometimes conduct feasibility studies. QMT only offers its expertise if the technical team deems the technology and know-how sufficiently mature to meet the requirement. QMT uses the ISO 16290 standard to define this maturity level (TRL: Technology Readiness Level). If the level is insufficient (below 6 out of 9), QMT 's Techlab is used by our experts to conduct the feasibility studies necessary for developing the required expertise.

Our Techlab is equipped to meet the needs of both mature technologies and new technologies.

- Traditional industrial vision equipment with a wide range of optics, lighting, cameras, and an optical bench with associated optical setups.

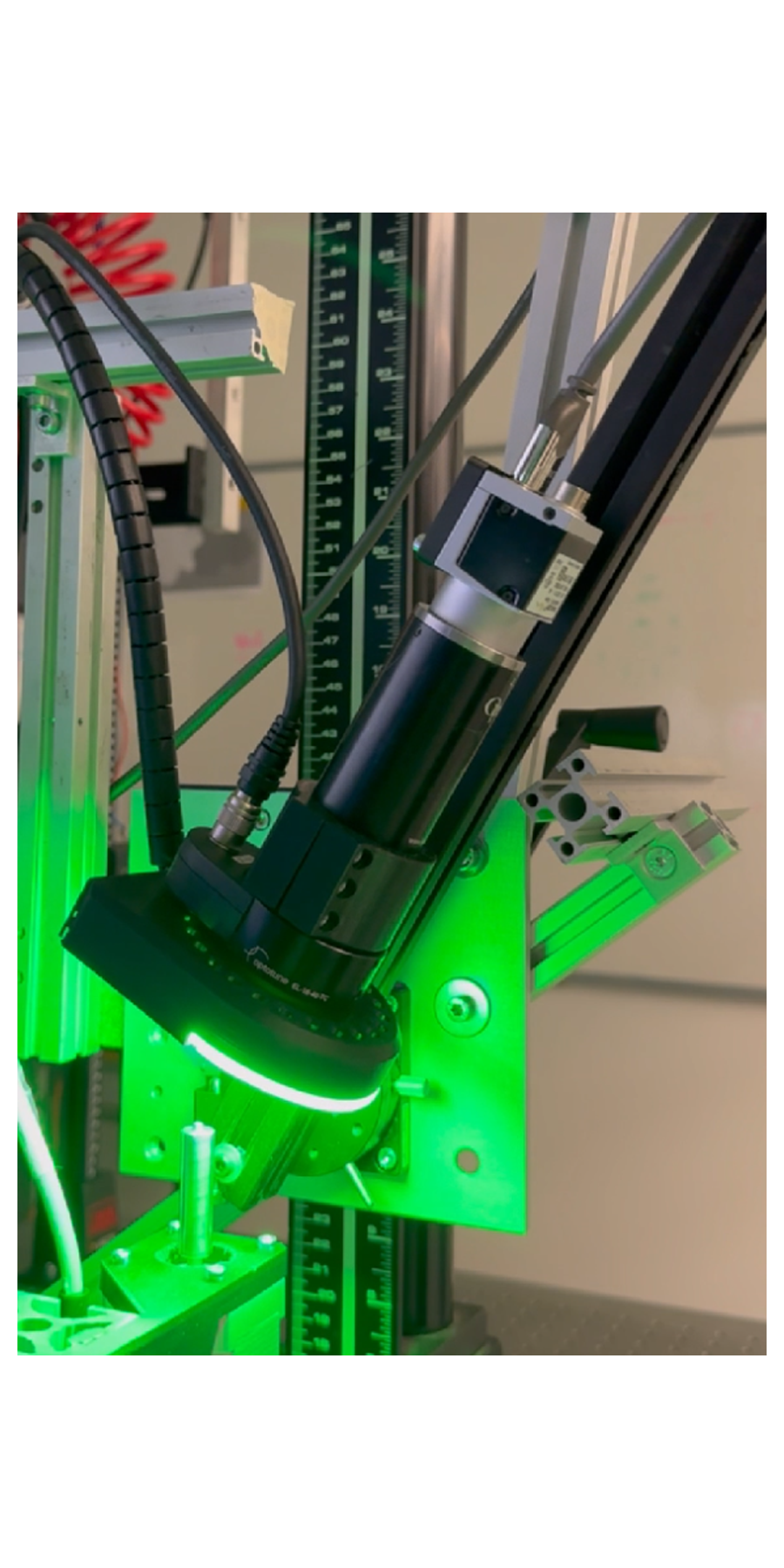

- Motorized bench equipped with chromatic confocal technology

- QMT multisens equipment enabling the combined acquisition of optical and acoustic signals

- Computer systems with analysis software

The services offered

Technical assistance and troubleshooting to keep your equipment in operational condition

Rapid availability of spare parts and a catalogue of certified standards to ensure metrological reliability

Motorized bench with chromatic confocal measurement technology

Chromatic confocal technology for optical distance and thickness measurement has been adopted as a proven method in industry and research. It is a perfect complement to traditional optics for in-plane measurement.

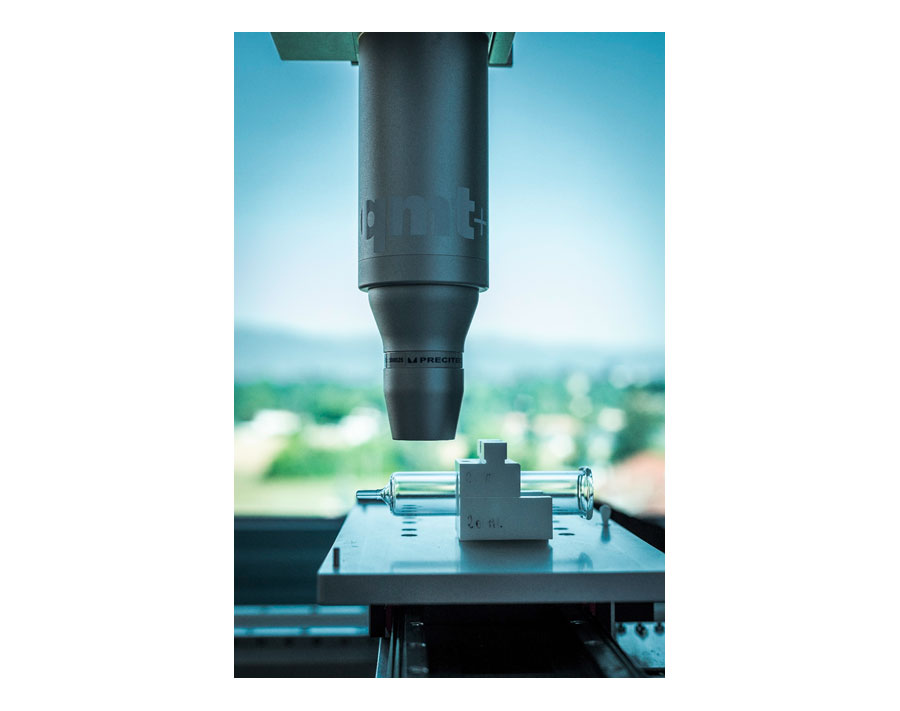

We have equipped our Techlab with a CVC (Chromatic Vision Camera) sensor. The CHRocodile CVC linear camera uses chromatic optics for 2D imaging. Chromatic confocal technology allows for both a significantly greater depth of field than standard cameras and exceptionally high lateral resolution. Requiring no focusing, this camera saves valuable time during quality inspections. By ensuring high contrast on all types of materials, the CHRocodile CVC is ideal for online or offline applications, such as cosmetic inspection and positioning detection.

By ensuring high contrast on all types of materials, the CVC CHRocodile is ideal for online or offline applications, such as cosmetic inspection and positioning detection.

- Linear motor axes with precision ball guides, self-lubricating with a large distance between guide rails for high torque moments

- Magnetic measuring system; 1μm resolution, +/- 8μm accuracy and reference marks for absolute positioning

- Stroke 320mm, Fn 60N, Fp 180N in X and Y, and 160mm in Z

- Robot guidance

- Depth of field of 3000μm, scan line length of 5.88mm

- Lateral resolution of 2.9μm; a maximum pixel count of 2048

- Option to add 3D measurement on the same lens

Fabrice Seyve and Claude Détée are ready to meet your needs for transparent part inspection, thickness measurements, or 3D characterization. Your parts will undergo our standard feasibility studies in our TechLab in Plan-les-Ouates or Barraux.